As a supplier of T5 Fixture Housing, I often receive inquiries from customers about the suitability of our products in various environments. One question that comes up frequently is whether T5 Fixture Housing can be used in a high - altitude environment. In this blog post, I'll explore this topic in detail, considering the scientific and practical aspects.

Understanding High - Altitude Environments

High - altitude environments are characterized by several factors that can potentially affect the performance of electrical fixtures. The most significant of these are lower air pressure, lower oxygen levels, and potentially extreme temperature variations.

At high altitudes, the air pressure is significantly lower than at sea level. For every 1000 meters increase in altitude, the air pressure drops by approximately 12%. This lower air pressure can have implications for the heat dissipation of electrical components. Heat is typically dissipated through convection, where air carries away the heat from the fixture. With lower air density at high altitudes, the convective heat transfer rate is reduced. This means that the T5 Fixture Housing may experience higher internal temperatures, which could potentially damage the electrical components inside.

Oxygen levels also decrease with increasing altitude. While this may not directly affect the operation of the T5 Fixture Housing, it can have an impact on the combustion characteristics in case of a malfunction. In normal conditions, oxygen is required for combustion. At high altitudes, the reduced oxygen levels may change the way a fire spreads or burns if there is an electrical fault.

Temperature variations in high - altitude areas can be extreme. During the day, the sun can heat up the environment significantly, while at night, the temperature can drop to very low levels. These rapid and large - scale temperature changes can cause materials to expand and contract, potentially leading to mechanical stress on the T5 Fixture Housing. Over time, this stress can cause cracks or other forms of damage to the housing.

Characteristics of T5 Fixture Housing

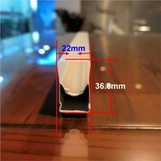

T5 Fixture Housing is designed to protect the internal electrical components of T5 fluorescent lamps. It is typically made of materials such as plastic or metal, each with its own set of properties.

Plastic T5 Fixture Housing is lightweight, corrosion - resistant, and relatively inexpensive. However, plastic materials can be sensitive to temperature changes. High temperatures can cause the plastic to soften and deform, while low temperatures can make it brittle and more prone to cracking. Metal T5 Fixture Housing, on the other hand, is more durable and has better heat - conducting properties. It can withstand higher temperatures without deforming, but it is heavier and more expensive.

The design of T5 Fixture Housing also plays a crucial role in its performance. Well - designed housings have proper ventilation channels to facilitate heat dissipation. However, in a high - altitude environment, the reduced air density may limit the effectiveness of these ventilation channels.

Performance in High - Altitude Environments

When it comes to using T5 Fixture Housing in a high - altitude environment, several factors need to be considered.

Heat Dissipation

As mentioned earlier, the reduced air density at high altitudes affects heat dissipation. To counter this, we can design T5 Fixture Housing with larger surface areas for heat transfer. For example, we can add fins or ridges to the housing to increase the contact area with the surrounding air. Additionally, using materials with better thermal conductivity can also help. Metal housings are generally better at dissipating heat compared to plastic ones.

Temperature Resistance

To withstand the extreme temperature variations in high - altitude environments, the materials used in T5 Fixture Housing need to have a wide temperature tolerance. For plastic housings, special additives can be used to improve their temperature resistance. These additives can enhance the plastic's ability to withstand both high and low temperatures without significant deformation or cracking.

Mechanical Durability

The mechanical stress caused by temperature changes can be mitigated by using materials with good mechanical properties. Metal housings are generally more resistant to mechanical stress compared to plastic ones. However, proper design is also important. For example, the housing can be designed with flexible joints or expansion gaps to allow for the expansion and contraction of materials without causing damage.

Comparison with Other Fixture Components

It's also interesting to compare T5 Fixture Housing with other related fixture components, such as the T8 Light Fixture Plastic Cover and T8 Light Fixture Cover. While T5 and T8 fixtures have different sizes and electrical requirements, the challenges they face in high - altitude environments are similar.

The plastic covers of T8 fixtures, like T5 Fixture Housing, are also sensitive to temperature changes. However, since they are mainly used for protection and light diffusion, their performance requirements may be slightly different. The Plastic Profiles used in these fixtures also need to be carefully selected to ensure they can withstand the environmental conditions at high altitudes.

Practical Applications and Case Studies

There have been several practical applications of T5 Fixture Housing in high - altitude areas. For example, in mountainous regions where infrastructure projects require lighting, T5 fixtures are sometimes used. In some cases, proper modifications were made to the housing to ensure its performance.

One case study involved a project in a high - altitude area where the T5 Fixture Housing was made of a special high - temperature - resistant plastic. The housing was also designed with additional ventilation holes to improve heat dissipation. After a year of operation, the fixtures showed no signs of significant damage or performance degradation, indicating that with proper design and material selection, T5 Fixture Housing can be used effectively in high - altitude environments.

Conclusion

In conclusion, while high - altitude environments pose several challenges for T5 Fixture Housing, it is possible to use them effectively with proper design and material selection. By considering factors such as heat dissipation, temperature resistance, and mechanical durability, we can ensure that the T5 Fixture Housing performs well in these challenging conditions.

If you are considering using T5 Fixture Housing in a high - altitude environment, or if you have any questions about our products, we are here to help. Our team of experts can provide you with detailed information and advice on the best solutions for your specific needs. Contact us to start a procurement discussion and find the perfect T5 Fixture Housing for your project.

References

- "Handbook of Environmental Engineering" by Philip H. Wilderer

- "High - Altitude Engineering and Technology" by various authors

- Industry reports on lighting fixture performance in extreme environments