Hey there! As a supplier of Extruded Linear Lenses, I've seen firsthand how crucial it is to test the optical performance of these lenses. In this blog, I'll walk you through the steps and methods to accurately test the optical performance of an extruded linear lens.

Why Test Optical Performance?

Before we dive into the testing methods, let's talk about why it's so important to test the optical performance of extruded linear lenses. These lenses are widely used in various lighting applications, such as LED Light Lens, LED Diffuser Strip, and Plastic Diffuser Lens. Their optical performance directly affects the quality of light output, including brightness, uniformity, and color accuracy. By testing the optical performance, we can ensure that the lenses meet the required standards and specifications, and provide the best lighting experience for our customers.

Tools and Equipment Needed

To test the optical performance of an extruded linear lens, you'll need the following tools and equipment:

- Spectrometer: A spectrometer is used to measure the spectral distribution of light, which can provide information about the color temperature, color rendering index (CRI), and other color-related parameters of the light output.

- Goniophotometer: A goniophotometer is used to measure the angular distribution of light, which can provide information about the beam angle, intensity distribution, and other beam-related parameters of the light output.

- Integrating Sphere: An integrating sphere is used to measure the total luminous flux of light, which can provide information about the overall brightness of the light output.

- Light Source: A light source is needed to illuminate the lens during the testing process. The light source should have a stable and uniform light output, and its spectral distribution should be similar to the intended application.

- Mounting Fixture: A mounting fixture is needed to hold the lens in place during the testing process. The mounting fixture should be designed to ensure that the lens is properly aligned and positioned, and that there is no interference or reflection from the fixture itself.

Testing Methods

There are several methods that can be used to test the optical performance of an extruded linear lens. Here are some of the most common methods:

Spectral Analysis

Spectral analysis is used to measure the spectral distribution of light, which can provide information about the color temperature, color rendering index (CRI), and other color-related parameters of the light output. To perform spectral analysis, you'll need a spectrometer and a light source. Here's how to do it:

- Mount the lens on the mounting fixture and position it in front of the light source.

- Turn on the light source and allow it to stabilize for a few minutes.

- Use the spectrometer to measure the spectral distribution of the light output from the lens.

- Analyze the spectral data using the spectrometer's software to determine the color temperature, CRI, and other color-related parameters of the light output.

Beam Analysis

Beam analysis is used to measure the angular distribution of light, which can provide information about the beam angle, intensity distribution, and other beam-related parameters of the light output. To perform beam analysis, you'll need a goniophotometer and a light source. Here's how to do it:

- Mount the lens on the mounting fixture and position it in front of the light source.

- Turn on the light source and allow it to stabilize for a few minutes.

- Use the goniophotometer to measure the angular distribution of the light output from the lens at different angles.

- Analyze the beam data using the goniophotometer's software to determine the beam angle, intensity distribution, and other beam-related parameters of the light output.

Luminous Flux Measurement

Luminous flux measurement is used to measure the total luminous flux of light, which can provide information about the overall brightness of the light output. To perform luminous flux measurement, you'll need an integrating sphere and a light source. Here's how to do it:

- Mount the lens on the mounting fixture and position it inside the integrating sphere.

- Turn on the light source and allow it to stabilize for a few minutes.

- Use the integrating sphere to measure the total luminous flux of the light output from the lens.

- Analyze the luminous flux data using the integrating sphere's software to determine the overall brightness of the light output.

Interpreting the Results

Once you've completed the testing process, you'll need to interpret the results to determine whether the lens meets the required standards and specifications. Here are some key parameters to look for:

- Color Temperature: The color temperature of the light output should be within the specified range for the intended application. For example, a color temperature of 2700K-3000K is typically used for warm white lighting, while a color temperature of 5000K-6500K is typically used for cool white lighting.

- Color Rendering Index (CRI): The CRI of the light output should be as high as possible, ideally above 90. A high CRI indicates that the light source can accurately reproduce the colors of objects, providing a more natural and vibrant lighting experience.

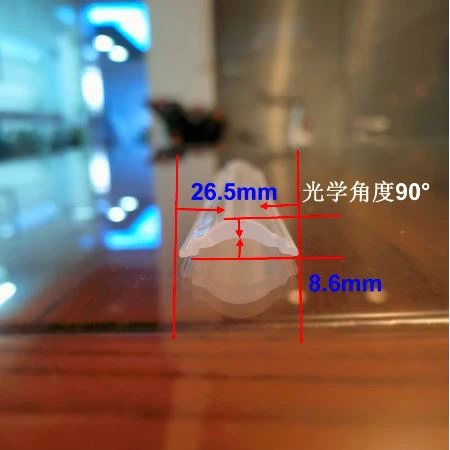

- Beam Angle: The beam angle of the light output should be within the specified range for the intended application. For example, a narrow beam angle of 10°-30° is typically used for spot lighting, while a wide beam angle of 60°-120° is typically used for flood lighting.

- Intensity Distribution: The intensity distribution of the light output should be uniform and symmetrical, with no hot spots or dark areas. A uniform intensity distribution ensures that the light is evenly distributed over the intended area, providing a more comfortable and visually appealing lighting experience.

- Luminous Flux: The luminous flux of the light output should be within the specified range for the intended application. A higher luminous flux indicates a brighter light output, while a lower luminous flux indicates a dimmer light output.

Conclusion

Testing the optical performance of an extruded linear lens is an important step in the manufacturing process, as it can ensure that the lenses meet the required standards and specifications, and provide the best lighting experience for our customers. By using the right tools and equipment, and following the proper testing methods, we can accurately measure the spectral distribution, angular distribution, and total luminous flux of the light output, and interpret the results to determine whether the lens meets the required standards and specifications. If you have any questions or need further assistance with testing the optical performance of an extruded linear lens, please don't hesitate to contact us. We're always here to help!

References

- "Optical Testing of LED Lenses," Lighting Research Center, Rensselaer Polytechnic Institute.

- "Spectral Analysis of Light Sources," National Institute of Standards and Technology (NIST).

- "Goniophotometry: Principles and Applications," Illuminating Engineering Society (IES).

- "Integrating Sphere Theory and Applications," Labsphere, Inc.