As a supplier of Lamp Cover Plastic, ensuring the high - quality of our products is of utmost importance. The quality of lamp cover plastic can significantly affect the performance, appearance, and durability of the lamps. In this blog, I will share some effective ways to test the quality of lamp cover plastic.

1. Visual Inspection

The first step in testing lamp cover plastic is a simple visual inspection. This can reveal many obvious quality issues.

- Color Consistency: Check if the color of the plastic is uniform throughout the lamp cover. Any color streaks, spots, or unevenness can be a sign of poor mixing during the manufacturing process. Inconsistent color can also affect the aesthetic appeal of the lamp. For example, if a lamp cover is supposed to be a pure white color, but there are yellowish patches, it not only looks unappealing but may also indicate a problem with the raw materials or the processing conditions.

- Surface Defects: Look for scratches, cracks, bubbles, or pits on the surface of the plastic. Scratches can reduce the light - transmission efficiency of the lamp cover and may also make it more prone to further damage. Cracks, on the other hand, can compromise the structural integrity of the cover, potentially leading to breakage during use. Bubbles or pits can cause uneven light distribution, creating a less - than - ideal lighting effect.

2. Light Transmission Test

One of the key functions of a lamp cover plastic is to transmit light effectively. A light transmission test can help evaluate this property.

- Transmittance Measurement: Use a spectrophotometer to measure the percentage of light that passes through the plastic. High - quality lamp cover plastic should have a high transmittance rate, typically above 80% for clear plastics. This ensures that the maximum amount of light from the lamp source can reach the surrounding environment. Different types of lamps may require different levels of light transmittance. For example, decorative lamps may allow for a slightly lower transmittance if they are designed to create a soft, diffused lighting effect, while task - lighting lamps usually need a higher transmittance for better visibility.

- Light Diffusion: In addition to transmittance, the way the plastic diffuses light is also important. A good lamp cover plastic should be able to evenly distribute the light, eliminating harsh shadows and hotspots. This can be tested by shining a light through the plastic onto a white surface and observing the light pattern. If the light is evenly spread without any concentrated areas of brightness, it indicates good light diffusion properties.

3. Mechanical Property Tests

The mechanical properties of lamp cover plastic determine its ability to withstand physical stress during handling, installation, and use.

- Tensile Strength: Conduct a tensile test to measure the maximum amount of tensile stress the plastic can withstand before breaking. A higher tensile strength means the plastic is more resistant to pulling forces. For example, if the lamp cover needs to be bent or stretched slightly during installation, a plastic with low tensile strength may break easily. This test is usually performed using a universal testing machine, which applies a gradually increasing pulling force until the specimen fails.

- Impact Resistance: Impact resistance is crucial as lamp covers may be accidentally knocked or dropped. An impact test can be carried out using a pendulum impact tester. The tester strikes the plastic sample with a pendulum of a known mass and velocity, and the energy absorbed by the plastic during the impact is measured. A high - impact - resistant plastic will be able to absorb more energy without cracking or shattering, ensuring the longevity of the lamp cover.

- Hardness Test: The hardness of the plastic affects its resistance to scratching and abrasion. A common method for testing hardness is the Rockwell or Shore hardness test. A harder plastic is less likely to be scratched by everyday objects, maintaining its appearance and light - transmission properties over time.

4. Chemical Resistance Test

Lamp cover plastics may be exposed to various chemicals during their lifetime, such as cleaning agents, solvents, or environmental pollutants. A chemical resistance test can assess how well the plastic can withstand these chemicals.

- Immersion Test: Immerse samples of the plastic in different chemicals for a specific period, such as 24 hours or 7 days. After the immersion, check for any changes in the plastic's appearance, such as discoloration, swelling, or softening. Also, measure its mechanical properties again to see if there has been any degradation. For example, if a lamp cover is likely to be cleaned with a particular type of solvent, it is important to ensure that the plastic is resistant to that solvent.

- Exposure to Environmental Chemicals: In addition to laboratory - based immersion tests, it is also beneficial to expose the plastic to real - world environmental chemicals. This can be done by placing the samples in an environment where they are likely to come into contact with common pollutants, such as near a busy road or in an industrial area. Regularly monitor the samples for any signs of damage over an extended period.

5. Thermal Resistance Test

Lamps generate heat, and the lamp cover plastic needs to be able to withstand this heat without deforming or degrading.

- Heat Deflection Temperature (HDT) Test: The HDT test measures the temperature at which the plastic begins to deform under a specific load. A higher HDT value indicates better thermal resistance. For example, in high - power lamps that generate a significant amount of heat, a plastic with a low HDT may warp or melt, affecting the performance and safety of the lamp.

- Thermal Aging Test: Subject the plastic samples to elevated temperatures for an extended period, typically in an oven. This simulates long - term exposure to heat during normal lamp use. After the thermal aging process, test the mechanical and optical properties of the samples again. Any significant changes in these properties indicate poor thermal stability of the plastic.

6. Weather Resistance Test

If the lamps are intended for outdoor use, the lamp cover plastic needs to be resistant to weather conditions, such as sunlight, rain, and temperature variations.

- UV Resistance Test: Ultraviolet (UV) rays from the sun can cause the plastic to degrade, leading to discoloration, embrittlement, and reduced mechanical properties. A UV resistance test can be performed using a UV chamber, which exposes the samples to artificial UV light for a set period. Compare the appearance and properties of the samples before and after the test to evaluate their UV resistance.

- Water Resistance Test: Immerse the plastic samples in water for a certain time and then check for any signs of water absorption, swelling, or delamination. Water - resistant plastic is essential for outdoor lamps to prevent damage from rain and humidity.

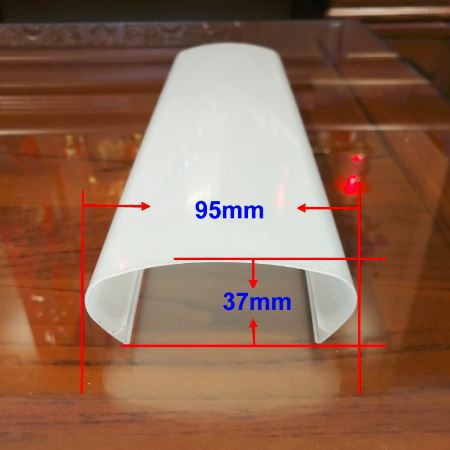

As a supplier of Lamp Cover Plastic, we are committed to providing high - quality products that meet all the necessary quality standards. Our Plastic Transparent Tube also undergoes similar rigorous testing procedures to ensure excellent performance. We are one of the leading Plastic Profile Extrusion Companies, and we take pride in our strict quality control measures.

If you are interested in purchasing our lamp cover plastic or have any questions about our products, please feel free to contact us for further discussions. We are more than happy to assist you in finding the best plastic solutions for your lamp manufacturing needs.

References

- ASTM International. Standard Test Methods for Plastics.

- ISO (International Organization for Standardization). Standards related to plastic testing.

- "Plastics Materials and Processing" by James F. Carley.