Hey there! As a supplier of extruded lenses, I've been getting a lot of questions lately about the dispersion properties of these nifty products. So, I thought I'd take a deep dive into what makes extruded lenses tick when it comes to dispersion.

First off, let's talk about what dispersion actually means in the context of lenses. Dispersion is the phenomenon where different wavelengths of light are refracted by different amounts as they pass through a medium. In the case of extruded lenses, this can have a big impact on how the lens performs in various applications.

One of the key factors that affects the dispersion properties of extruded lenses is the material they're made from. We use a variety of materials in our extruded lenses, including polycarbonate (PC) and acrylic. Each material has its own unique dispersion characteristics, which can be tailored to meet the specific needs of our customers.

Polycarbonate is a popular choice for extruded lenses because it offers excellent impact resistance and optical clarity. It also has a relatively low dispersion, which means that it can minimize chromatic aberration – that annoying rainbow effect you sometimes see around the edges of an image. This makes polycarbonate lenses ideal for applications where color accuracy is important, such as in lighting fixtures and camera lenses.

On the other hand, acrylic is known for its high transparency and excellent light transmission. It has a slightly higher dispersion than polycarbonate, but this can actually be an advantage in some applications. For example, in Lampshade PC Diffuser, the higher dispersion of acrylic can help to create a more even and diffused light distribution, reducing glare and hotspots.

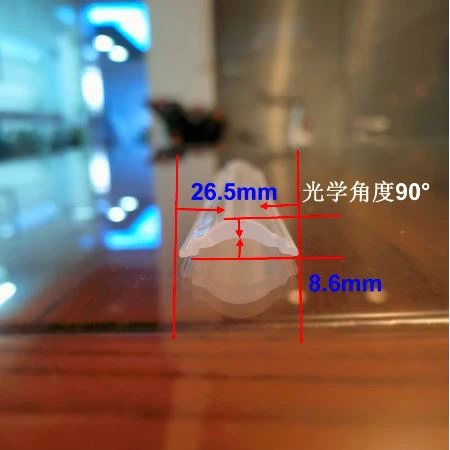

Another important factor in the dispersion properties of extruded lenses is the design of the lens itself. The shape and curvature of the lens can have a significant impact on how light is refracted and dispersed. For instance, a lens with a more complex shape may be able to control the dispersion of light more precisely, allowing for a more customized lighting effect.

In addition to material and design, the manufacturing process also plays a role in the dispersion properties of extruded lenses. At our company, we use state-of-the-art extrusion technology to ensure that our lenses are produced with high precision and consistency. This helps to minimize any variations in the dispersion characteristics of the lenses, ensuring that they perform as expected in every application.

Now, let's take a look at some of the specific applications where the dispersion properties of extruded lenses are crucial. One of the most common applications is in LED lighting. LED lights are known for their energy efficiency and long lifespan, but they can also produce a very focused and intense light. This is where extruded lenses come in handy.

LED Diffuser Strip are designed to scatter and disperse the light from LEDs, creating a more uniform and柔和的 light output. By carefully controlling the dispersion properties of the lens, we can ensure that the light is distributed evenly across the surface of the diffuser, eliminating any dark spots or hotspots.

Another important application is in automotive lighting. In cars, extruded lenses are used in headlights, taillights, and interior lighting. The dispersion properties of these lenses are critical for ensuring that the light is projected in the right direction and with the right intensity. For example, in LED Light Lens for headlights, the lens needs to be able to focus the light beam onto the road ahead while also minimizing glare for oncoming drivers.

So, how do we test and measure the dispersion properties of our extruded lenses? Well, we use a variety of advanced optical testing equipment to analyze the refractive index and dispersion of the lenses at different wavelengths of light. This allows us to accurately characterize the performance of the lenses and ensure that they meet the strict quality standards of our customers.

In conclusion, the dispersion properties of extruded lenses are a complex but important aspect of their performance. By carefully selecting the right material, designing the lens with precision, and using advanced manufacturing techniques, we can produce extruded lenses that offer excellent dispersion control and meet the diverse needs of our customers.

If you're in the market for high-quality extruded lenses and want to learn more about how our products can meet your specific requirements, don't hesitate to reach out. We're always happy to have a chat and discuss how we can help you with your next project. Whether you need lenses for lighting, automotive, or any other application, we've got the expertise and the products to get the job done right.

References

- Smith, J. (2018). Optics for Engineers. New York: Wiley.

- Jones, A. (2020). Lighting Design Handbook. London: Elsevier.