When it comes to T5 LED fixtures, one often overlooked yet crucial component is the cover. The thickness of a typical T5 LED fixture cover can significantly impact its performance, durability, and overall aesthetic appeal. As a trusted supplier of T5 LED Fixture Covers, I am here to shed light on this important topic.

Understanding the Role of T5 LED Fixture Covers

Before delving into the thickness, it's essential to understand what T5 LED fixture covers do. These covers serve multiple purposes. Firstly, they protect the internal components of the LED fixture, such as the bulbs and wiring, from dust, moisture, and physical damage. Secondly, they diffuse the light emitted by the LEDs, creating a more even and pleasant illumination. Thirdly, they contribute to the overall look of the fixture, enhancing its visual appeal in various settings.

Factors Influencing the Thickness of T5 LED Fixture Covers

Several factors play a role in determining the appropriate thickness of a T5 LED fixture cover.

Material

The material used to make the cover is a primary factor. Common materials include polycarbonate, acrylic, and PVC. Polycarbonate is known for its high impact resistance and durability, so it can often be thinner while still providing adequate protection. Acrylic, on the other hand, offers excellent optical clarity but may require a slightly greater thickness to achieve the same level of strength. PVC is a cost - effective option, and its thickness may vary depending on the specific application and required performance.

Application

The environment in which the T5 LED fixture will be used also affects the cover thickness. In industrial settings where the fixture may be exposed to more physical stress, a thicker cover is usually preferred. For example, in a factory with moving machinery, a thicker polycarbonate cover can withstand accidental impacts. In a residential or commercial office environment, where the risk of damage is lower, a thinner cover may be sufficient.

Light Diffusion Requirements

If the goal is to achieve a high level of light diffusion, the cover thickness may need to be adjusted. A thicker cover can often provide better diffusion, as the light has more material to pass through, scattering it more effectively. However, this needs to be balanced with the need to maintain sufficient light output.

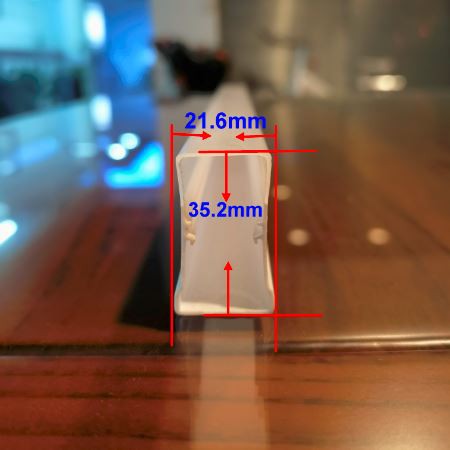

Typical Thickness Ranges

Based on industry standards and common applications, the thickness of a typical T5 LED fixture cover can range from 1mm to 3mm.

1mm - 1.5mm

Covers in this thickness range are often used in applications where cost - efficiency and lightweight design are priorities. They are suitable for residential settings, such as living rooms, bedrooms, and kitchens, where the risk of physical damage is relatively low. These thinner covers also allow for a higher percentage of light transmission, which can be beneficial in areas where bright illumination is desired.

1.5mm - 2mm

This is a more common thickness range for commercial applications, such as offices, retail stores, and restaurants. The covers in this range offer a good balance between light diffusion, strength, and cost. They can withstand normal wear and tear and provide adequate protection for the internal components of the LED fixture.

2mm - 3mm

Thicker covers in this range are typically used in industrial or high - traffic areas. They are more resistant to impacts and can withstand harsh environmental conditions. For example, in a warehouse or a manufacturing plant, a 2mm - 3mm thick polycarbonate cover can protect the LED fixture from dust, debris, and accidental collisions.

Our Offerings as a T5 LED Fixture Cover Supplier

As a supplier of T5 LED Fixture Covers, we understand the importance of providing the right thickness for different applications. We offer a wide range of covers made from high - quality materials, including polycarbonate, acrylic, and PVC. Our covers are available in various thicknesses, allowing our customers to choose the option that best suits their needs.

We also provide custom - made solutions. If you have specific requirements for the thickness, size, or shape of the cover, our team of experts can work with you to develop a tailored product. Our manufacturing process ensures that each cover meets the highest quality standards, providing long - lasting performance and reliability.

In addition to T5 LED fixture covers, we also offer related products such as Plastic Profiles, LED Light Fixture Housing, and Extruded Plastic Profiles. These products are designed to work seamlessly with our T5 LED fixture covers, providing a complete lighting solution.

Why Choose Our T5 LED Fixture Covers

- Quality Assurance: We source the best materials and use advanced manufacturing techniques to ensure that our covers are of the highest quality. Each cover undergoes rigorous testing to meet industry standards.

- Customization: We understand that every customer has unique needs. That's why we offer customization options to provide the perfect solution for your specific application.

- Competitive Pricing: We strive to offer our products at competitive prices without compromising on quality. Our cost - effective solutions make it easier for you to manage your budget.

- Excellent Customer Service: Our team is dedicated to providing excellent customer service. We are available to answer your questions, provide technical support, and assist you throughout the purchasing process.

Contact Us for Procurement

If you are interested in purchasing T5 LED fixture covers or need more information about our products, we encourage you to get in touch with us. Our sales team is ready to discuss your requirements, provide detailed product information, and offer competitive quotes. Whether you are a small business owner looking for a few covers or a large - scale distributor in need of bulk orders, we have the capacity to meet your needs.

References

- "LED Lighting Handbook" - A comprehensive guide on LED lighting technology and components.

- Industry reports on the manufacturing and use of T5 LED fixtures.

- Technical specifications from leading material suppliers for polycarbonate, acrylic, and PVC.