As a leading supplier of LED plastic covers, I am often asked about the availability of different textures for these essential components. In this blog post, I will delve into the world of LED plastic cover textures, exploring the various options available, their benefits, and how they can enhance the functionality and aesthetics of your lighting solutions.

The Importance of Texture in LED Plastic Covers

Texture plays a crucial role in the performance and appearance of LED plastic covers. It can affect how light is diffused, reflected, and absorbed, ultimately influencing the overall quality of the illumination. Additionally, texture can add a unique visual element to the cover, enhancing the design and style of the lighting fixture.

Available Textures for LED Plastic Covers

There are several textures available for LED plastic covers, each with its own distinct characteristics and benefits. Here are some of the most common textures:

- Matte Texture: A matte texture provides a soft, non - reflective surface that diffuses light evenly. This texture is ideal for applications where glare reduction is a priority, such as in office lighting, hospitals, and schools. Matte - textured LED plastic covers can also give a more sophisticated and modern look to the lighting fixture. Lamp Cover Plastic often comes in matte finishes for these reasons.

- Satin Texture: Similar to the matte texture, the satin texture offers a smooth, low - sheen surface. It provides a balance between light diffusion and a bit of reflectivity, creating a warm and inviting glow. Satin - textured covers are commonly used in residential lighting, such as in living rooms and bedrooms, to create a cozy atmosphere.

- Prismatic Texture: Prismatic textures are designed to manipulate light in specific ways. These textures consist of small, angled prisms that can refract and reflect light, enhancing brightness and creating interesting lighting effects. Prismatic LED plastic covers are often used in commercial settings, such as retail stores and warehouses, to maximize light output and highlight products.

- Stippled Texture: A stippled texture features a pattern of small dots or bumps on the surface of the plastic cover. This texture helps to scatter light and reduce hotspots, resulting in a more uniform illumination. Stippled - textured covers are suitable for a variety of applications, including pendant lights and wall sconces.

- Woodgrain Texture: For a more natural and rustic look, woodgrain - textured LED plastic covers are available. These covers mimic the appearance of real wood, adding a touch of warmth and charm to the lighting fixture. Woodgrain textures can be a great choice for interior design themes that incorporate natural elements, such as cabins or bohemian - style homes.

Benefits of Different Textures

Each texture offers unique benefits that can be tailored to specific lighting requirements. Here are some of the advantages of using different textures in LED plastic covers:

- Improved Light Distribution: Textured covers can help to distribute light more evenly, reducing shadows and hotspots. This is especially important in large - scale lighting installations, where uniform illumination is essential.

- Glare Reduction: Matte and satin textures are effective at reducing glare, making the lighting more comfortable for the eyes. This is beneficial in areas where people need to work or read, such as offices and libraries.

- Enhanced Aesthetics: Different textures can add visual interest and style to the lighting fixture. Whether you prefer a modern, sleek look or a more traditional, rustic feel, there is a texture to suit your design preferences.

- Customization: The availability of various textures allows for greater customization of lighting solutions. You can choose a texture that complements the overall design of the space and meets the specific lighting needs of the application.

Applications of Textured LED Plastic Covers

Textured LED plastic covers are used in a wide range of lighting applications, including:

- Residential Lighting: In homes, textured covers can be found in ceiling lights, wall sconces, pendant lights, and table lamps. They help to create a comfortable and inviting atmosphere in different rooms.

- Commercial Lighting: Commercial spaces such as offices, retail stores, restaurants, and hotels benefit from the use of textured LED plastic covers. These covers can enhance the visual appeal of the space and improve the quality of lighting for customers and employees.

- Industrial Lighting: In industrial settings, such as factories and warehouses, prismatic and stippled textures are often used to maximize light output and ensure uniform illumination across large areas.

- Outdoor Lighting: Textured LED plastic covers can also be used in outdoor lighting fixtures, such as streetlights and landscape lights. They can protect the LEDs from the elements while providing the desired lighting effect.

Manufacturing and Quality Assurance

As a supplier of LED plastic covers, we understand the importance of high - quality manufacturing processes. Our covers are produced using advanced plastic extrusion techniques, which allow for precise control over the texture and other properties of the plastic. We work with Plastic Profile Extrusion Companies that have a proven track record of excellence in the industry.

We also conduct rigorous quality control checks to ensure that our LED plastic covers meet the highest standards. This includes testing for light transmission, durability, and resistance to environmental factors such as UV rays and moisture. Our commitment to quality ensures that our customers receive reliable and long - lasting products.

Choosing the Right Texture for Your Application

When choosing a texture for your LED plastic cover, there are several factors to consider:

- Lighting Requirements: Determine the level of light diffusion, brightness, and glare reduction needed for your application. For example, if you need to reduce glare in an office setting, a matte or satin texture would be a good choice.

- Aesthetic Preferences: Consider the overall design and style of the space where the lighting fixture will be installed. Choose a texture that complements the existing decor and enhances the visual appeal of the area.

- Environmental Conditions: If the lighting fixture will be used outdoors or in a harsh environment, choose a texture that is resistant to UV rays, moisture, and other environmental factors.

- Cost: Different textures may have different production costs, which can affect the price of the LED plastic cover. Consider your budget when making a decision.

Our Product Range

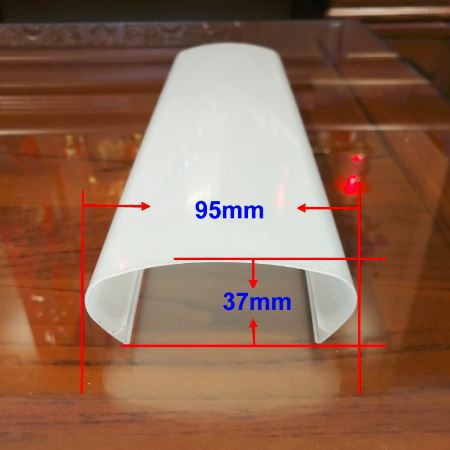

We offer a wide range of LED plastic covers with different textures to meet the diverse needs of our customers. Our T8 Tube Plastic Cover is available in various textures, including matte, satin, and prismatic, to provide the perfect lighting solution for your T8 tube lights. Whether you are looking for a cover for a residential, commercial, or industrial application, we have the right product for you.

Conclusion

In conclusion, LED plastic covers are indeed available in different textures, each offering unique benefits and applications. The choice of texture depends on various factors, including lighting requirements, aesthetic preferences, environmental conditions, and cost. As a supplier, we are dedicated to providing high - quality textured LED plastic covers that meet the needs of our customers.

If you are interested in learning more about our LED plastic covers or would like to discuss your specific requirements, we invite you to contact us for a procurement discussion. We are ready to assist you in finding the perfect lighting solution for your project.

References

- "Lighting Design Handbook" by Keith H. Boyce

- "Plastic Extrusion Technology" by John A. Brydson

- Industry reports on LED lighting and plastic cover manufacturing.