Can T8 tube covers be used in a warehouse? This is a question that many warehouse owners and managers often ask. As a supplier of T8 Tube Covers, I'd like to share some insights on this topic.

Advantages of Using T8 Tube Covers in a Warehouse

1. Protection

Warehouses are often bustling places with a lot of activities. Forklifts, pallet jacks, and workers moving around can accidentally hit the lighting fixtures. T8 tube covers act as a shield, protecting the fluorescent tubes from physical damage. A damaged tube not only needs to be replaced, which incurs costs, but it can also pose safety hazards such as broken glass and exposed electrical components. By using T8 Tube Plastic Cover, the lifespan of the T8 tubes can be significantly extended, reducing the frequency of replacements and maintenance.

2. Light Diffusion

In a warehouse, uniform lighting is crucial for safety and efficient operations. T8 tube covers are designed to diffuse light evenly. Without a cover, the light from the fluorescent tubes can be harsh and create shadows, making it difficult for workers to see clearly, especially in areas with high shelves or complex layouts. The Lamp Cover Plastic helps to spread the light more uniformly across the warehouse floor, reducing glare and improving visibility. This can enhance worker productivity and reduce the risk of accidents.

3. Energy Efficiency

Some T8 tube covers are made of materials that can enhance the reflectivity of light. By reflecting more light towards the working area, these covers can effectively increase the amount of usable light without increasing the power consumption of the lighting system. This means that with the use of Plastic Light Cover, warehouses can achieve the same level of illumination with less energy, resulting in cost savings on electricity bills.

4. Hygiene and Cleanliness

Warehouses may store various types of goods, including food, pharmaceuticals, and sensitive electronics. Dust, dirt, and other contaminants can accumulate on the lighting fixtures over time. T8 tube covers prevent these particles from settling directly on the tubes. They are also easier to clean compared to the tubes themselves. Regular cleaning of the covers can help maintain a clean and hygienic environment in the warehouse, which is especially important for industries with strict hygiene requirements.

Considerations When Using T8 Tube Covers in a Warehouse

1. Material Selection

The material of the T8 tube cover is a critical factor. It should be durable enough to withstand the rough environment in a warehouse. Common materials include polycarbonate and acrylic. Polycarbonate is known for its high impact resistance, making it suitable for warehouses with heavy machinery and high - traffic areas. Acrylic, on the other hand, offers good light transmission and is relatively lightweight. When choosing a cover, it's important to consider the specific needs of the warehouse, such as the level of physical activity and the required light quality.

2. Compatibility

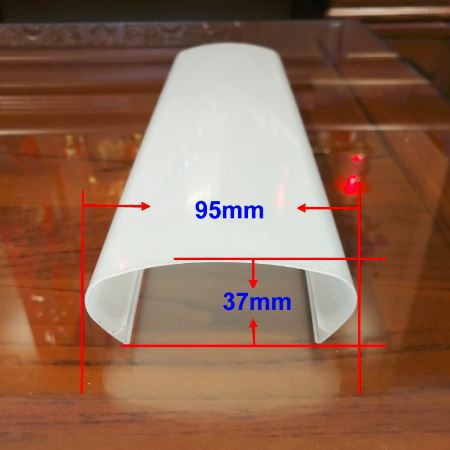

Not all T8 tube covers are compatible with every type of T8 tube. It's essential to ensure that the cover is the right size and shape for the tubes used in the warehouse. An ill - fitting cover may not provide proper protection or light diffusion. Additionally, some covers may be designed for specific types of lighting fixtures, so it's important to check the compatibility before making a purchase.

3. Installation

Proper installation of T8 tube covers is necessary to ensure their effectiveness. Incorrect installation can lead to problems such as poor light diffusion, loose covers that may fall off, or even damage to the tubes. It's recommended to follow the manufacturer's installation instructions carefully. If possible, professional installation services can be considered, especially for large - scale warehouse lighting systems.

Case Studies

Let's take a look at some real - world examples of how T8 tube covers have been used in warehouses.

A large food distribution warehouse was facing issues with broken tubes due to the constant movement of forklifts. After installing T8 tube covers made of high - impact polycarbonate, the number of tube replacements decreased significantly. The covers also improved the overall lighting quality, making it easier for workers to pick and pack products accurately. As a result, the warehouse saw an increase in productivity and a reduction in maintenance costs.

Another warehouse that stored electronics was concerned about dust accumulation on the lighting fixtures. By using T8 tube covers, they were able to keep the tubes clean and prevent dust from interfering with the light output. The covers were easy to clean, and the uniform light distribution improved the working conditions for employees who needed to perform detailed inspections on the products.

Conclusion

In conclusion, T8 tube covers can be a valuable addition to a warehouse lighting system. They offer protection, improve light quality, enhance energy efficiency, and contribute to a clean and hygienic environment. However, it's important to carefully consider the material, compatibility, and installation to ensure optimal performance.

If you're a warehouse owner or manager interested in improving your lighting system with T8 tube covers, I encourage you to reach out for more information. We are a professional supplier of T8 Tube Covers, and we can provide you with high - quality products and professional advice. Whether you have a small - scale warehouse or a large industrial facility, we have the right solutions for you. Contact us to start a discussion about your specific needs and how our T8 tube covers can benefit your warehouse.

References

- "Industrial Lighting Handbook", published by a leading lighting industry association.

- Case studies collected from various warehouses that have implemented T8 tube covers.