As a supplier of plastic light covers, I understand the importance of providing high - quality products to our customers. In the market, there is a wide range of plastic light covers available, and it can be challenging for consumers to determine which ones are of good quality. In this blog, I will share some key factors to help you tell if a plastic light cover is of good quality.

1. Material Quality

The material used in a plastic light cover is the foundation of its quality. High - quality plastic light covers are typically made from polymers that offer excellent optical properties, durability, and heat resistance.

Optical Clarity

One of the primary functions of a plastic light cover is to diffuse light evenly while maintaining a certain level of clarity. Good - quality plastic should have high optical clarity, which means that it allows light to pass through with minimal distortion. You can test the optical clarity by holding the light cover up to a light source. If you can see a clear and sharp image through the cover, it indicates good optical properties. For example, polycarbonate is a popular choice for plastic light covers because of its high optical clarity, which makes it suitable for applications where clear and bright lighting is required.

Durability

A durable plastic light cover can withstand various environmental factors, such as temperature changes, humidity, and physical impact. Look for materials that are resistant to cracking, scratching, and yellowing over time. For instance, acrylic is known for its good durability and weather resistance. It can maintain its appearance and performance even when exposed to sunlight and harsh weather conditions. To test the durability, you can try gently scratching the surface of the light cover with a soft object. If there are no visible scratches, it suggests that the plastic has good scratch - resistance.

Heat Resistance

Since light fixtures generate heat, a plastic light cover needs to have sufficient heat resistance to prevent deformation or melting. High - quality plastics can withstand the heat generated by the light source without warping. You can check the heat resistance specifications provided by the manufacturer. For example, some engineering plastics are designed to have high heat - deflection temperatures, which means they can maintain their shape and integrity at relatively high temperatures.

2. Manufacturing Process

The manufacturing process plays a crucial role in determining the quality of a plastic light cover.

Precision Molding

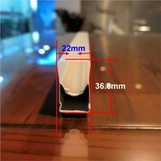

A well - made plastic light cover should have precise dimensions and a smooth surface finish. Precision molding ensures that the cover fits perfectly on the light fixture and provides a seamless appearance. Look for covers that have consistent wall thickness and no visible seams or burrs. For example, injection molding is a common manufacturing process for plastic light covers. It allows for high - precision production, resulting in products with accurate shapes and dimensions.

Quality Control

Reputable manufacturers implement strict quality control measures throughout the manufacturing process. This includes inspecting the raw materials, monitoring the production process, and conducting final product testing. A good quality plastic light cover should meet industry standards and specifications. You can ask the supplier about their quality control procedures and certifications. For example, ISO 9001 certification indicates that the manufacturer has a quality management system in place to ensure consistent product quality.

3. Design and Functionality

The design and functionality of a plastic light cover also contribute to its overall quality.

Light Diffusion

The main purpose of a light cover is to diffuse light evenly, reducing glare and creating a more comfortable lighting environment. A good - quality light cover should have a well - designed light diffusion pattern. You can test the light diffusion by installing the cover on a light fixture and observing the lighting effect. The light should be evenly distributed without any dark spots or hot spots. For example, some plastic light covers are designed with micro - patterns on the surface to enhance light diffusion.

Compatibility

A high - quality plastic light cover should be compatible with the specific light fixture it is intended for. It should fit securely and not cause any issues with the installation or operation of the light. Check the product specifications to ensure that the cover is suitable for your light fixture in terms of size, shape, and mounting method. For instance, Tube Light Plastic Cover is designed to be compatible with tube lights, providing a perfect fit and optimal lighting performance.

Aesthetics

In addition to functionality, the aesthetics of a plastic light cover are also important. It should enhance the overall appearance of the light fixture and the surrounding environment. Look for covers with a clean and modern design that complements the style of your space. The color and finish of the cover should also be consistent and free from any defects.

4. Brand Reputation and Supplier Reliability

The brand reputation and supplier reliability are important indicators of the quality of a plastic light cover.

Brand Reputation

Well - established brands with a good reputation in the market are more likely to produce high - quality products. You can research the brand online, read customer reviews, and check industry ratings. A brand that has been in the business for a long time and has positive feedback from customers is usually a reliable choice. For example, some brands are known for their commitment to innovation and quality, and they invest in research and development to improve their products continuously.

Supplier Reliability

As a supplier, we understand the importance of providing reliable products and services. A reliable supplier should be able to offer technical support, after - sales service, and timely delivery. You can ask the supplier about their production capacity, lead time, and customer service. For example, a supplier that can provide customized solutions and respond quickly to your inquiries is more likely to meet your needs.

5. Price - Quality Ratio

While price is not always an accurate indicator of quality, it can provide some clues.

Overly Cheap Products

If a plastic light cover is significantly cheaper than others on the market, it may be a sign of poor quality. Low - cost products may be made from inferior materials or produced using substandard manufacturing processes. These products are more likely to have issues with durability, optical clarity, and heat resistance.

High - End Products

On the other hand, high - end products are usually priced higher because of their superior quality, advanced features, and better brand reputation. However, it doesn't mean that you always have to choose the most expensive option. You need to balance the price and quality based on your specific requirements. For example, if you are looking for a plastic light cover for a commercial space where high - quality lighting is essential, it may be worth investing in a more expensive but better - quality product.

6. Certification and Standards

Certification and compliance with industry standards are important for ensuring the quality and safety of plastic light covers.

Industry Standards

Look for plastic light covers that meet relevant industry standards, such as UL (Underwriters Laboratories) standards in the United States or CE (Conformité Européene) marking in Europe. These standards ensure that the product has been tested and meets specific safety and performance requirements. For example, UL - listed plastic light covers have been tested for flammability, electrical safety, and other important factors.

Environmental Standards

In addition to safety standards, environmental standards are also becoming increasingly important. Choose plastic light covers that are made from recyclable materials or comply with environmental regulations, such as RoHS (Restriction of Hazardous Substances). This not only helps to protect the environment but also indicates that the manufacturer is committed to sustainable production.

In conclusion, determining the quality of a plastic light cover requires a comprehensive evaluation of various factors, including material quality, manufacturing process, design and functionality, brand reputation, price - quality ratio, and certification. As a supplier of plastic light covers, we are committed to providing high - quality products that meet the needs of our customers. If you are interested in purchasing T8 Tube Plastic Cover or other plastic light covers, or if you have any questions about our products, please feel free to contact us for further discussion and procurement negotiation. We are looking forward to serving you and establishing a long - term business relationship.

References

- Plastics Industry Association. (n.d.). Plastic Materials and Their Properties.

- Underwriters Laboratories. (n.d.). UL Standards for Lighting Products.

- European Union. (n.d.). CE Marking Regulations.