As a supplier of T8 fixture housing, I am often asked about the technical specifications of these essential components in the lighting industry. T8 fixture housing plays a crucial role in protecting the internal components of T8 fluorescent or LED lamps and providing a stable structure for installation. In this blog, I will delve into the key technical specifications of T8 fixture housing, shedding light on its design, materials, dimensions, and other important aspects.

Design and Structure

The design of T8 fixture housing is carefully engineered to ensure optimal performance and functionality. It typically consists of a long, narrow body that can accommodate the T8 lamp tube. The housing may have different shapes, such as rectangular or circular, depending on the specific application and aesthetic requirements.

One of the primary functions of the housing is to provide mechanical protection for the lamp. It shields the lamp from physical damage, such as impacts and vibrations, which could otherwise lead to premature failure. Additionally, the housing helps to prevent dust, moisture, and other contaminants from entering the lamp, ensuring its long - term reliability.

The structure of the T8 fixture housing also includes provisions for mounting the lamp and electrical components. It may have holes or slots for screws or clips to secure the lamp in place. Some housings are designed for easy installation and maintenance, allowing for quick replacement of the lamp or other parts.

Materials

The choice of materials for T8 fixture housing is critical as it affects the housing's durability, heat dissipation, and overall performance. Commonly used materials include plastics and metals.

Plastics

Plastic materials are widely used in T8 fixture housing due to their numerous advantages. They are lightweight, which makes them easy to handle and install. Plastics also offer good electrical insulation properties, reducing the risk of electrical shock.

One popular type of plastic used is polycarbonate. Polycarbonate is known for its high impact resistance, transparency, and heat resistance. It can withstand a wide range of temperatures without deforming, making it suitable for both indoor and outdoor applications. Another plastic option is PVC (polyvinyl chloride), which is cost - effective and has good chemical resistance.

You can find a variety of Extrusion Plastic Cover and Plastic Profiles on our website, which are designed to meet different requirements of T8 fixture housing.

Metals

Metal materials, such as aluminum, are also used in T8 fixture housing, especially in applications where heat dissipation is a major concern. Aluminum has excellent thermal conductivity, which helps to transfer heat away from the lamp and other electrical components. This can extend the lifespan of the lamp and improve its performance.

Metal housings are generally more durable and can withstand harsh environments better than plastic housings. They are also less likely to be damaged by UV radiation, making them suitable for outdoor use. However, metal housings are heavier and more expensive than plastic housings, and they require proper corrosion protection to prevent rusting.

Dimensions

The dimensions of T8 fixture housing are standardized to ensure compatibility with T8 lamp tubes. The most common length of T8 fixture housing corresponds to the length of the T8 lamp, which is typically 4 feet (1219 mm) or 8 feet (2438 mm).

The width and height of the housing are designed to accommodate the lamp tube and other components. The inner width of the housing should be slightly larger than the diameter of the T8 lamp, which is usually around 1 inch (25.4 mm). This allows for easy insertion and removal of the lamp.

The outer dimensions of the housing may vary depending on the design and the presence of additional features, such as heat sinks or mounting brackets. It is important to ensure that the housing dimensions are suitable for the intended installation location and that they comply with relevant industry standards.

Heat Dissipation

Heat dissipation is a crucial factor in the performance and lifespan of T8 lamps. When the lamp is in operation, it generates heat, and if this heat is not dissipated effectively, it can cause the lamp to overheat, leading to reduced efficiency and a shorter lifespan.

T8 fixture housing is designed to help with heat dissipation. As mentioned earlier, metal housings, particularly those made of aluminum, have good thermal conductivity and can transfer heat away from the lamp. Some plastic housings are also designed with features such as fins or vents to improve air circulation and heat dissipation.

In LED T8 fixtures, heat dissipation is even more important as LEDs are sensitive to high temperatures. An efficient LED Light Fixture Housing can help to keep the LED chips at an optimal operating temperature, ensuring their long - term performance and reliability.

Electrical Insulation

Electrical insulation is another important technical specification of T8 fixture housing. The housing must provide adequate insulation to prevent electrical current from leaking and to protect users from electrical shock.

Plastic materials are inherently good electrical insulators, and they are often used in the construction of T8 fixture housing for this reason. Metal housings, on the other hand, need to be properly insulated to ensure electrical safety. This can be achieved through the use of insulating coatings or by incorporating insulating components within the housing.

Sealing and Protection

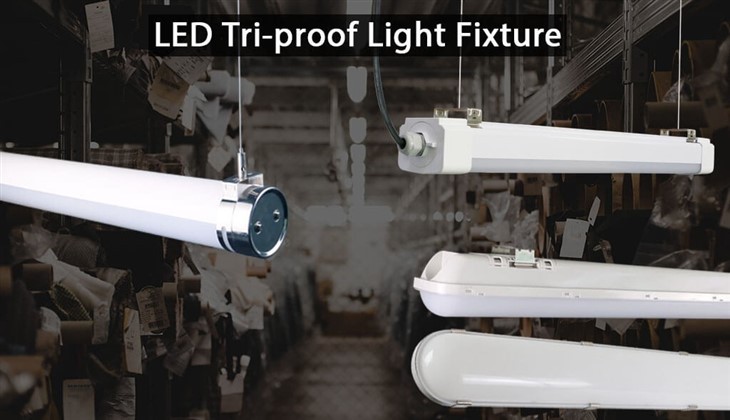

T8 fixture housing may need to provide protection against environmental factors such as dust, moisture, and water. In outdoor or industrial applications, the housing should be sealed to prevent the ingress of these contaminants.

Some housings are designed with gaskets or seals to create a watertight or dust - tight enclosure. These seals are typically made of rubber or silicone materials, which can provide a good seal even under different temperature and humidity conditions. The level of protection is often indicated by an IP (Ingress Protection) rating, which specifies the degree of protection against solid objects and water.

Conclusion

In conclusion, the technical specifications of T8 fixture housing are complex and diverse, covering aspects such as design, materials, dimensions, heat dissipation, electrical insulation, and sealing. As a supplier, we understand the importance of meeting these specifications to provide high - quality products to our customers.

If you are in the market for T8 fixture housing, we invite you to contact us for more information and to discuss your specific requirements. Our team of experts can help you choose the right housing based on your application, budget, and performance needs. We are committed to providing excellent products and services to ensure your satisfaction.

References

- Lighting Industry Association Standards

- Technical manuals of plastic and metal materials used in fixture housing